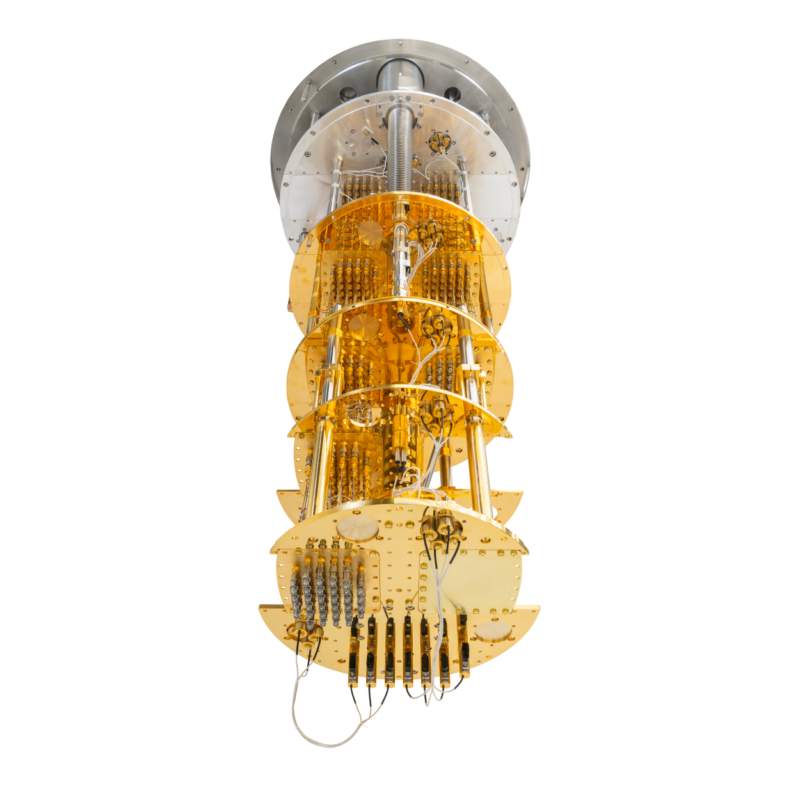

The LD System has the largest amount of available options and different magnet configurations that allow it to be customized for different experiments and uses.

The LD400 system typically provides more than 15 μW at 20 mK on the experimental flange with only 18 liters of helium-3. In addition, it has a high cooling power of ∼ 0.5 mW when operated at 100 mK.

There is now a new LD System configuration with side-loading ports. The LD400sl System includes 2 side-loading ports to enable the simple and convenient installation of our side-loading wiring.

This well-engineered dilution refrigerator measurement system has a clean and open design for installing measurement equipment. A single push of a button initiates a fully automated cooldown sequence from room to base temperature.

Product Highlights

1.0

LD

Dilution Refrigerator Measurement System

Gas Handling System & Control Software Generation 2

Services

Total System Care

Total System Care enables you to focus on your work—carrying out research, operating quantum computers, and driving innovation—now, and over the full lifetime of your system.

Tailored to your specific needs, you’ll benefit from a package with an agreed service level and accompanying set of field services that ensure your systems operate at the best possible performance level.

Technical Specifications

2.0

LD

Dilution Refrigerator Measurement System

Pulse Tube Cryocooler Configurations

3.0

LD

Dilution Refrigerator Measurement System

Options

4.0

LD

Dilution Refrigerator Measurement System

Performance Graphs

5.0

LD

Dilution Refrigerator Measurement System

Services

Customer Care

We support our customers throughout the lifetime of their system, providing dedicated care to find solutions for any issues. Our technicians and engineers are ready to help you wherever you are located, with prompt service delivered either remotely or on-site.

Related Products

Layout and Facility Requirements

6.0

LD

Dilution Refrigerator Measurement System

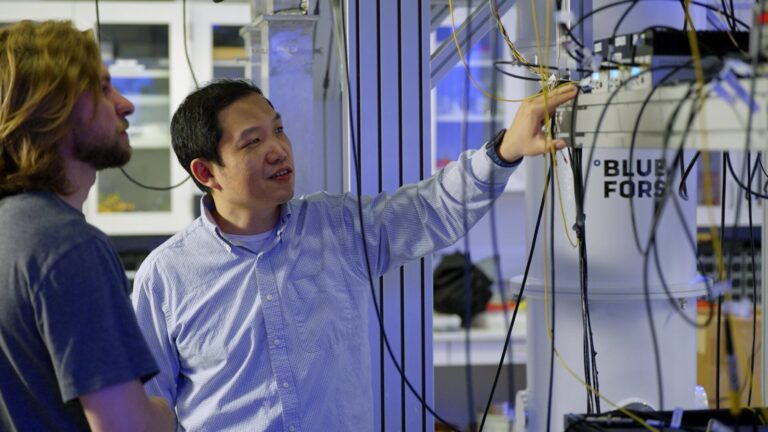

LD Systems Empowering Research

See Also