Control Software Generation 2 – Cool Power at Your Fingertips

The Gas Handling System is the beating heart that powers every Bluefors dilution refrigerator, managing the helium gas circulation throughout the system. When we decided it was time to design a new, more powerful Gas Handling System, we wanted to begin that process with the end user, placing a strong focus on how we can improve the experience of using the system for our customers.

With that in mind, it was clear that the design process shouldn’t begin with the hardware, but with the software: the primary interface that every user interacts with on a daily basis.

Design Goals

With 1200+ systems in use around the world – including some that have been in operation for over 15 years – we’ve received a lot of feedback and usage information from customers. We know what people want to achieve with our systems, and have also learned about the stumbling blocks that might get in the way of their progress.

Until now, our existing Gas Handling System has proven to be a good solution, but we wanted to take it further. Improving the hardware would only be half the story. We wanted to improve the entire system to deliver a better experience for users. We were aware that we could make the hardware as powerful as we liked, but in the end it’s only as good as the software controlling it. Our goal was to bring our Control Software up to the same level of excellence as Bluefors’ hardware products.

From a design perspective, we began to look at some of the best mobile phone applications for ideas and benchmarks. We wanted to create the same kind of user experience you get on your phone: familiar, easy to use yet surprisingly powerful, and built on a solid, robust backend.

We wanted to give users a more intuitive experience that give them full control over all device parameters if they wanted that, but also to make key tasks much simpler. We’ve designed the entire system to be intelligent enough to automate an entire cooldown with just a couple of clicks, but powerful enough so that you can really dive into all the data and diagnostics if you need to.

First Steps and Development

Development of the software began with in-depth interviews with both our internal team and customers to identify the key areas we needed to improve. After many discussions and ideation rounds, we identified a fundamental set of use cases and functionality needed, and settled on a development framework through which we could address them.

For the design, we wanted to create a clear, simple architecture that would allow users to control the system in all conditions, and give a clearer illustration of the various states of the dilution refrigerator during cooldown.

Our internal software development team grew to around 15 people, including front- and back-end developers, dev-ops teams, internal and external testers and designers. We also collaborated with Taiste, an award-wining digital solutions company based in Helsinki, to polish the software and deliver an uncompromising solution and UX/UI that is truly next generation.

The Finished Product

With our new touch screen operated control software, you can take a deep dive into all aspects of the system, and get incredibly detailed, intuitive access to all the controls and the diagnostic data. Through its modern UI, you can access a huge set of device parameters, detect errors and give alerts, utilize an internal database, and enjoy increased automation to free up time for your work. Being browser based, you also get enhanced remote access, including the ability to remotely control your magnets.

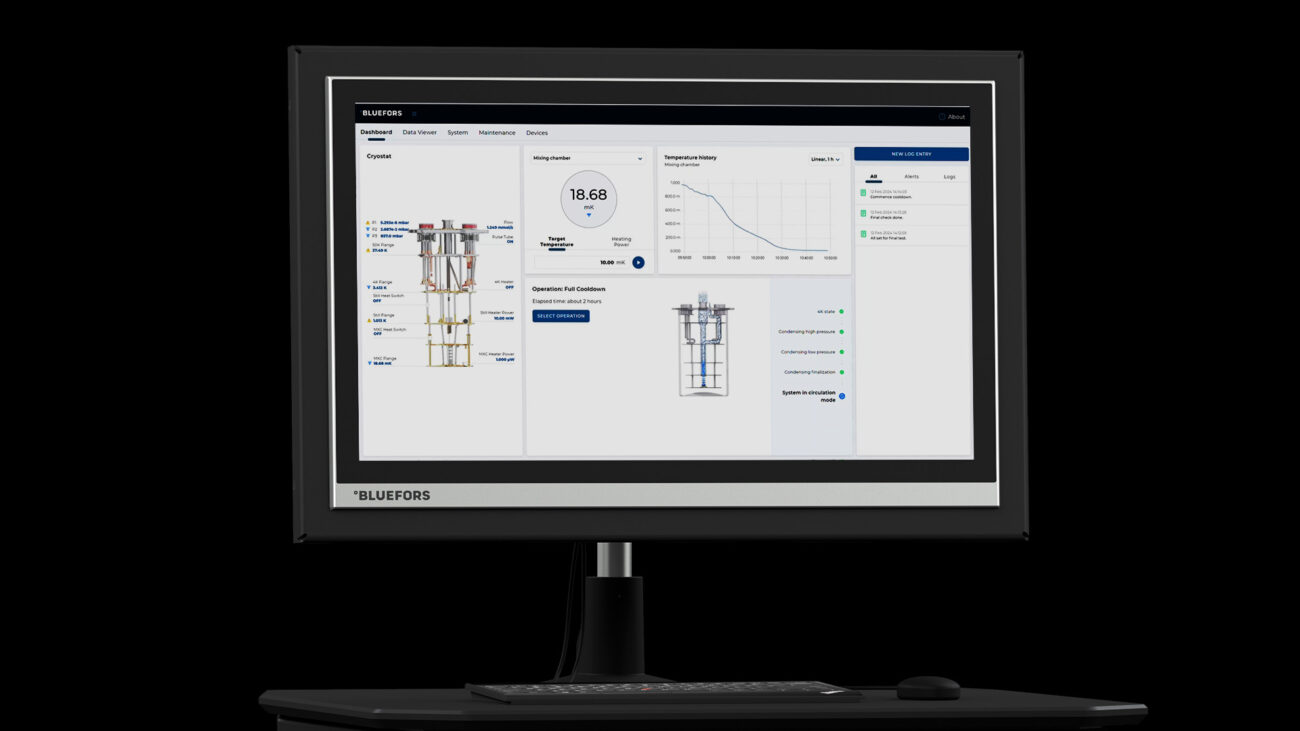

The core view of the software is based around a live System Dashboard, showing an up-to-date overview of the cryostat, current status and operation, a temperature history, and any alerts.

A fully configurable Data Viewer allows you to track multiple sensors and data points.

The familiar System Overview has been enhanced with live data, clear representation of valve states, and key functions can now be individually operated with a single tap. A comprehensive device list provides enhanced data for every gauge, pump, controller, or other device.

Automation now allows users to simple select an operation (such as cooldown) and let the software take care of everything.

And the enhanced remote access means you can access your system remotely, with remote magnet control offered for the first time. The optional redesigned Fast Sample Exchange can also be operated via the software or directly on the unit.

The new Control Software has also been designed to identify any potential issues, and a Maintenance View helps you keep everything up and running. Ultimately, this delivers more peace of mind and contributes to longer system lifetimes.

Proud of the Achievement

Control Software Generation 2 has been designed to be familiar for existing users, but also easy to step in as a new user and start using it. At the same time, the level of data, information and control has been enormously enhanced. Once you start to use it and explore the power and flexibility it now offers, it completely transforms the experience of using a Bluefors system.

We’re truly excited to finally be able to deliver this with the new Gas Handling System, and we can’t wait to see how our customers make use of the advanced capabilities.

Our Generation 2 Gas Handling System and Control Software have been designed in tandem as a modular platform that can be upgraded and improved for many years to come. For us, the next stage of development now begins: creating new features that will take the system and our users even further into the quantum future. Stay tuned!

For further information about our Generation 2 Gas Handling System and Control Software, contact our sales engineers.

Join also our webinar on Gas Handling System Generation 2.

To stay up to date with the latest Bluefors and Cryomech news, subscribe to our newsletter.