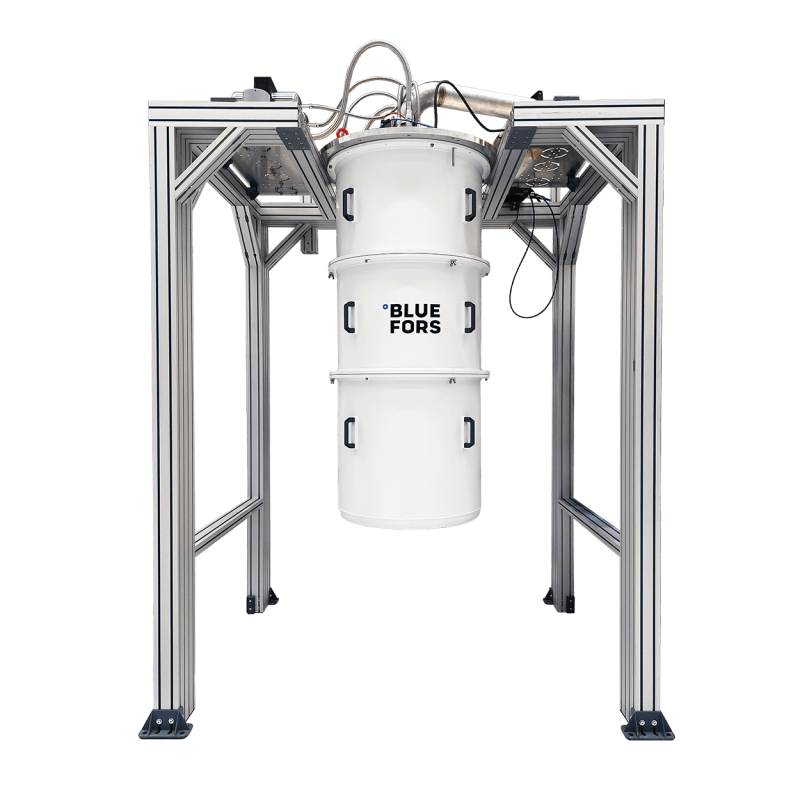

Bluefors cryogen-free Dilution Refrigerator Measurement Systems are industry-leading, top-of-the-line cooling systems. They provide continuous cooling at ultra-low temperatures through the dilution process of helium-3–helium-4 mixture in a closed-loop environment.

Our next-generation Gas Handling System provides extensive new control capabilities and advanced hardware solutions utilizing an all-new Control Software with unprecedented ease-of-use.

Product Highlights

1.0

Dilution Refrigerator Measurement Systems

Products

Services

Total System Care

Total System Care enables you to focus on your own work – doing research and measurements. The service ensures that systems operate at the best possible performance level and with maximal uptime, without users needing to spend time maintaining the systems themselves.

Systems

2.0

Dilution Refrigerator Measurement Systems

Products

Gas Handling System & Control Software Generation 2

System Comparison

3.0

Dilution Refrigerator Measurement Systems

Products

Note: Cooling power is measured on experimental flange outside MXC.

| SD | LH | LD250 | LD400 | LD400sl | XLD400sl | XLD1000sl | |

|---|---|---|---|---|---|---|---|

| Cooling | |||||||

| Standard pulse tube configuration | 1 x PT410 | 1 x PT415 | 1 x PT415 | 1 x PT415-ENH | 1 x PT415-ENH | 2 x PT415 | 2 x PT425-ENH |

| Other available pulse tube models | PT415, PT420, PT425, PT310 | PT420, PT425 | PT410, PT420, PT425, PT310 | PT425-ENH, PT310-ENH | PT425-ENH, PT310-ENH | 2 x PT420, 2 x PT425, PT310 & PT425 | PT310-ENH & PT425-ENH, 3 x PT425-ENH |

| Typical cooling power (µW) at 20 mK | N/A | 13 | 14 | 16 | 16 | 16 | 30 |

| Typical cooling power (µW) at 100 mK | 250 | 300 | 300 | 500 | 500 | 450 | 1000 |

| Guaranteed base temperature (mK) | <30 | <10 | <10 | <10 | <10 | <10 | <10 |

| Mechanical features | |||||||

| MXC Flange diameter (mm) | 148 | 294 | 294 | 294 | 294 | 500 | 500 |

| Dilution Unit placement | edge | edge | edge | edge | edge | center | center |

| Dilution Unit type | short | horizontal | standard | standard | standard | standard | dual |

| Standard experimental ports The number of available ports depends on the options and wiring configuration. | |||||||

| KF25 | 1 | ||||||

| KF40 | 2 | 4 | 5 | 5 | 4 | 7 | 7 |

| K63 | 2 | 2 | 2 | ||||

| Side-loading ports | 2 | 6 | 6 | ||||

| Maximum number of coaxial cables | 14 (SMA) | 70 (SMA) | 77 (SMA) | 77 (SMA) | 336 HDW & 28 (SMA), 92 (SMA only) | >1000 (HDW) | >1000 (HDW) |

Services

Customer Care

We support our customers throughout the lifetime of their system, providing dedicated care to find solutions for any issues. Our technicians and engineers are ready to help you wherever you are located, with prompt service delivered either remotely or on-site.

Options and Related Products

4.0

Dilution Refrigerator Measurement Systems

Products

Frequently Asked Questions

5.0

Dilution Refrigerator Measurement Systems

Products

Bluefors Dilution Refrigerators Empowering Research

See Also