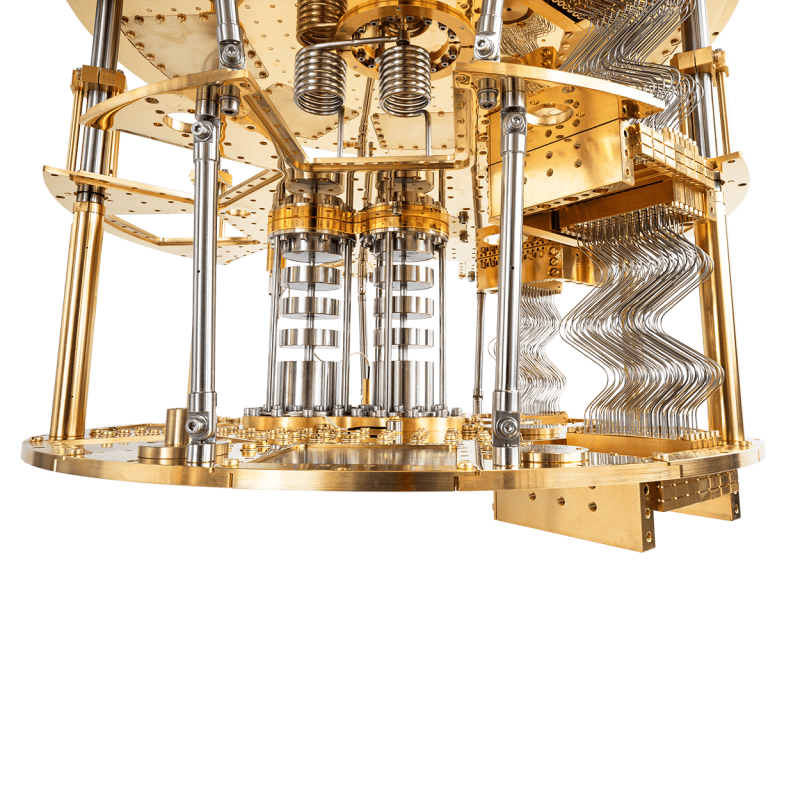

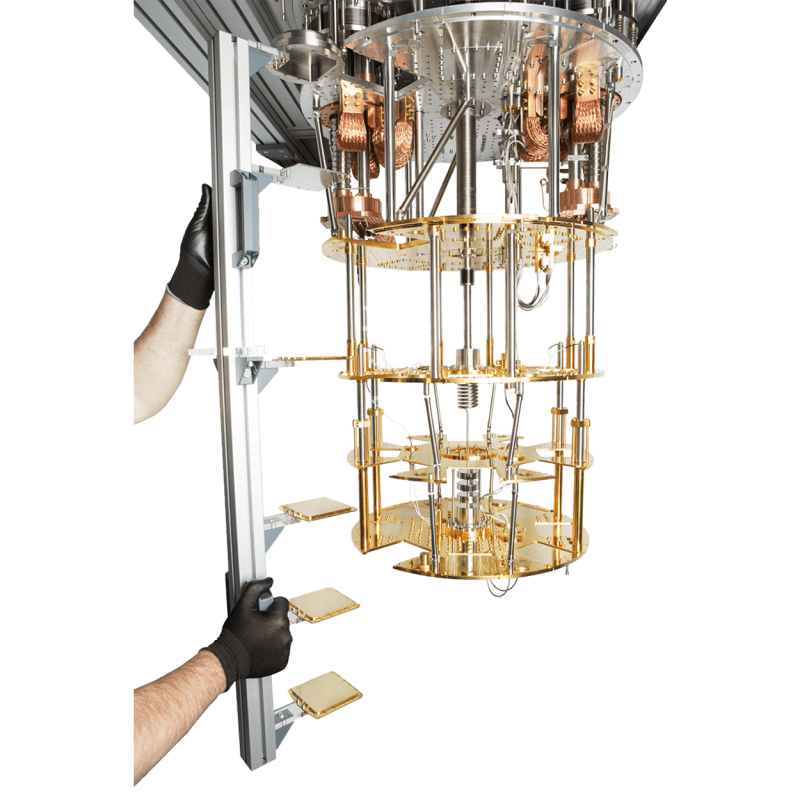

The XLDsl accommodates up to 1008 factory-installed semi-rigid 18 GHz coaxial lines in a configuration with two pulse tubes. Its side-loading feature allows experimental wiring to be prepared away from the cryostat while the system is running.

Even with its extensive capabilities and superior performance, a fully automated cool-down sequence from room to base temperature can still be carried out at the push of a single button.

Product Highlights

1.0

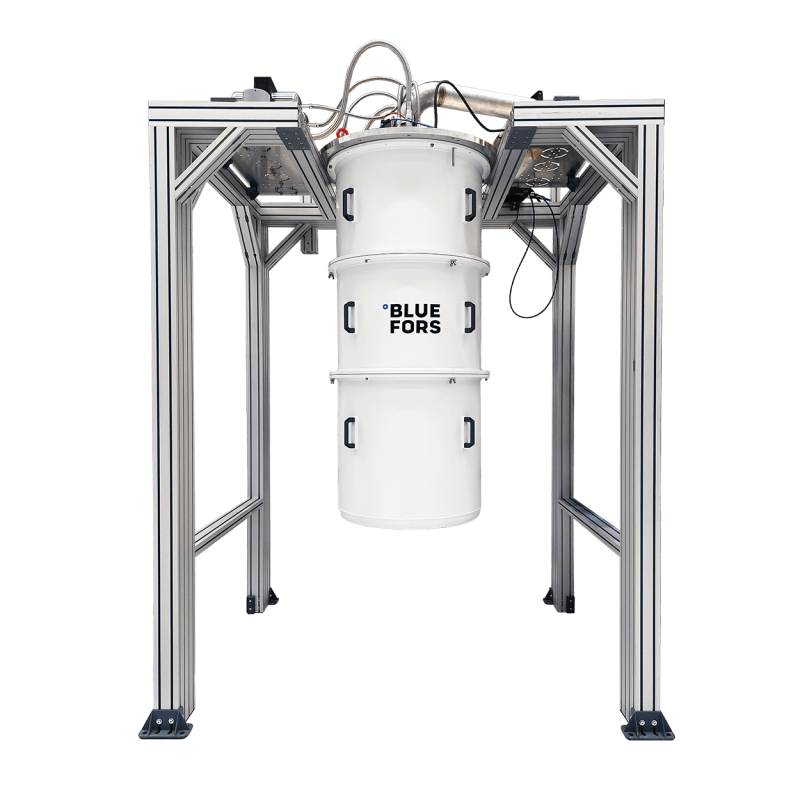

XLDsl

Dilution Refrigerator Measurement System

Gas Handling System & Control Software Generation 2

Services

Total System Care

Total System Care enables you to focus on your own work – doing research and measurements. The service ensures that systems operate at the best possible performance level and with maximal uptime, without users needing to spend time maintaining the systems themselves.

Technical Specifications

2.0

XLDsl

Dilution Refrigerator Measurement System

Pulse Tube Cryocooler Configurations

3.0

XLDsl

Dilution Refrigerator Measurement System

Options

4.0

XLDsl

Dilution Refrigerator Measurement System

Performance Graphs

5.0

XLDsl

Dilution Refrigerator Measurement System

Services

Customer Care

We support our customers throughout the lifetime of their system, providing dedicated care to find solutions for any issues. Our technicians and engineers are ready to help you wherever you are located, with prompt service delivered either remotely or on-site.

Related Products

Layout and Facility Requirements

6.0

XLDsl

Dilution Refrigerator Measurement System

See Also