Cryomech HeRL02-RM Helps Ohio State University Achieve Closed-Loop Helium Recovery for Ultra-High-Field NMR Magnet

Can you run a pumped NMR magnet system in a closed loop? Thanks to the Cryomech HeRL02‑RM, the answer is a resounding yes.

On June 10, 2025, the Ohio State University successfully commissioned a Cryomech helium reliquefier for their Bruker UltraStabilized 800 MHz NMR system—a pumped magnet operating at the cutting edge of spectroscopy. With the HeRL02-RM Ohio State can now recycle 100% of their helium, eliminating boil-off and drastically reducing operational costs and supply risk.

Read on to learn why this milestone installation marks a significant leap forward in sustainability for high-field NMR research.

What is a ‘Pumped’ 2 K Magnet?

Ultra-high-field (UHF) NMR magnets are superconducting magnets used in nuclear magnetic resonance (NMR) spectroscopy. These systems operate at extremely high magnetic field strengths, typically defined as 800 MHz (1H frequency, 18.8 T) and above. They are primarily used in advanced scientific fields such as structural biology and material science.

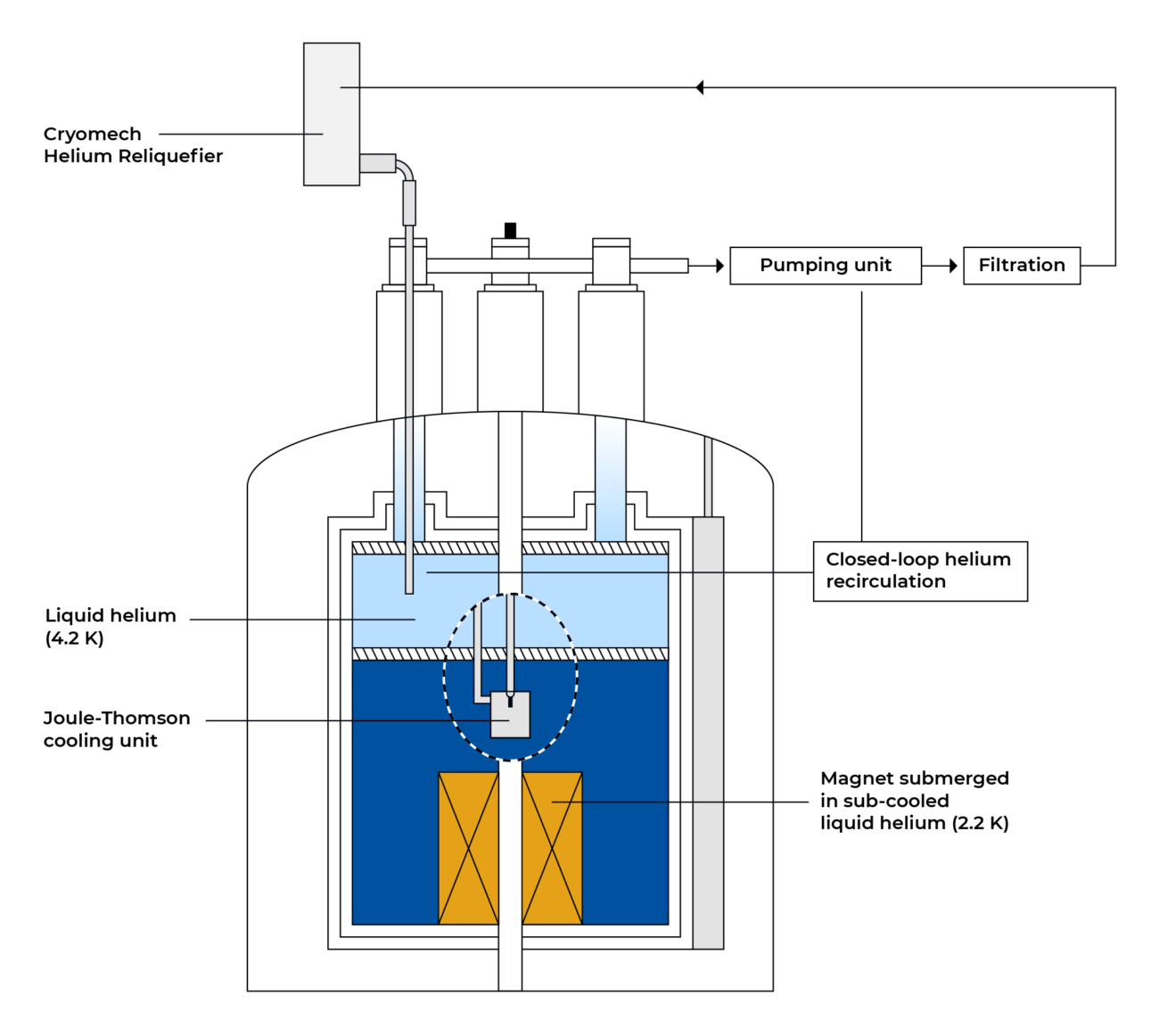

The primary benefit of these high fields is a dramatic improvement in spectral resolution and sensitivity, which is critical for detailed molecular analysis. However, to achieve stable operation at these field strengths using low-temperature superconductors (LTS), the magnet’s superconducting coils must be cooled well below the normal 4.2 K boiling point of liquid helium. These “pumped” systems use a vacuum pump to reduce the pressure above the liquid helium bath, forcing it to boil at a lower temperature of approximately 1.8–2 K. This 2 K operation was a key feature of the first 900 MHz UHF magnets and remains essential for systems like the 800 MHz magnet at Ohio State.

In a pumped system, the helium bath is connected to a vacuum pump which reduces the pressure above the liquid helium. This results in the helium boiling at a lower temperature (in much the same way that water boils at a lower temperature at higher altitudes and lower air pressure). These lower temperatures improve superconducting performance and stability in ultra-high-field magnets, and enable higher magnetic fields.

Ultra-high-field NMR magnets are extraordinary tools for science, but they come with a hidden cost: helium consumption. When helium boils, just like water, it evaporates. An 800 MHz magnet typically evaporates around four liters of liquid helium a day. In an era of global helium shortages and rising prices, that loss can add up to an expensive additional running cost. Systems must be frequently refilled, which take away precious time for experiments.

This is precisely where the Cryomech HeRL02-RM can help. By creating a closed-loop reliquefication solution, the HeRL02-RM captures, reliquefies, and returns every molecule of evaporated helium back to the magnet, allowing Ohio State University to recycle 100% of the helium used, dramatically reducing operational costs and eliminating refills.

Installation and Validation

While the HeRL02‑RM was designed specifically for single-NMR systems, the OSU NMR Lab team, led by Dr. Alex Hansen, partnered with Bluefors to carefully integrate the system and accommodate the magnet’s unique plumbing and vibration sensitivity. To achieve this, a slightly larger cryocooler configuration was selected to meet the additional requirements, which in turn necessitated additional testing to ensure there were no performance hits.

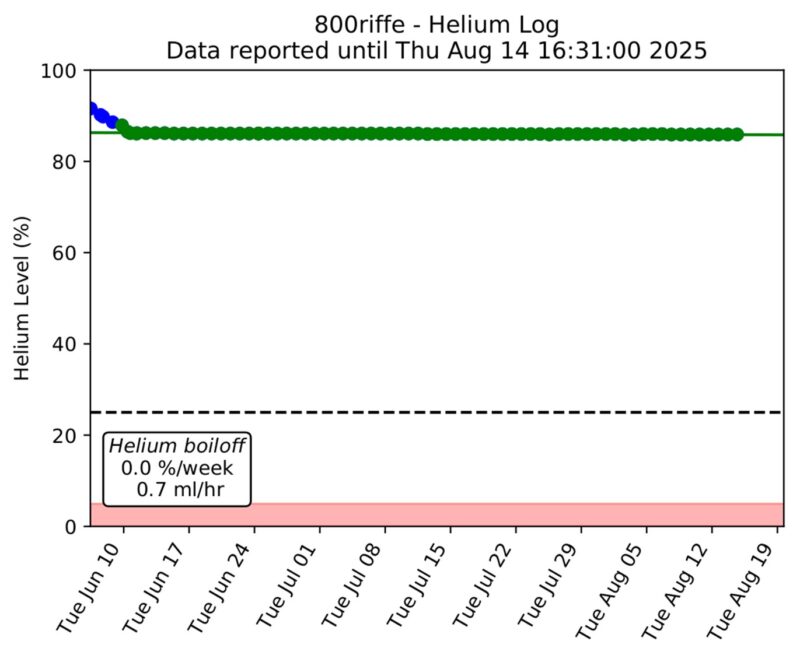

After completing the mechanical integration, electrical interlocks, and system cooldown, the team began the validation process. The first step was to monitor the reliquefier’s core function and stability, carefully tracking helium levels and reliquefication rates. The critical test, however, was confirming that the new hardware had zero impact on the spectrometer’s sensitive measurements.

To verify this, the team performed a direct comparison of spectrometer performance before and after the installation. They specifically analyzed line shape, signal-to-noise ratio, and vibration data. The results were definitive: the closed-loop operation introduced no measurable impact on data quality, confirming the installation as a complete success.

With the HeRL02-RM handling helium recovery, and the existing CryoProbe and nitrogen liquefier also operating in a closed loop, the entire system now has no routine cryogenic maintenance requirements and can operate indefinitely.

The helium recirculation results were equally positive. After running continuously since commissioning, the system had efficiently maintained helium levels without the need for any refills. The magnet’s dewar, which previously saw a steady helium level depletion, now shows a flat line—proof of true zero-loss operation. For the Ohio State research team, this means uninterrupted access to ultra-high-field NMR without the logistical headaches and interruptions of helium deliveries and refills.

Uninterrupted Progress

The Ohio State installation demonstrates that closed-loop helium recovery is not only possible for 2 K magnets, it’s also practical and reliable. As more labs adopt this approach, the scientific community can reduce its dependence on a finite resource while maintaining the performance standards demanded by advanced spectroscopy research.

“Our collaboration with Bluefors began in 2023 with our 600 MHz reliquefier,” Dr. Hansen explains. “We were so impressed that we pushed them to develop a solution for our pumped magnets, which represented over 80% of our helium consumption. The Bluefors team was incredibly diligent, demonstrating a level of expertise on par with the magnet’s original engineers.

“The result is transformative. The solution eliminates the need for the enormous gas bag and a host of support equipment, freeing our staff from the daily logistics of helium transfers to focus on research. Financially, this system is so affordable it will pay for itself in just a few years, finally delivering the sustainable solution our community has needed. We are eager to continue this partnership as we move to equip our next systems.”

At Bluefors, we’d like to extend our thanks to Dr. Alex Hansen and the entire NMR Lab team at Ohio State University for their vision and collaboration. Their leadership ensures that cutting-edge research continues without compromise—and without waste.

To find out how the Cryomech HeRL02-RM can reduce your helium refill costs, contact our sales team.