The Ultra-Compact LD System is an all-in-one, ultra-compact cryogenic measurement system based on our LD systems.

The new, compact, cryogenic measurement system is ideal for laboratory environments with limited space, or as a solution for high-performance computing (HPC) data centers where multiple units need to be installed in the same space. It is built to operate silently with low vibration, making it perfect for noise-sensitive environments.

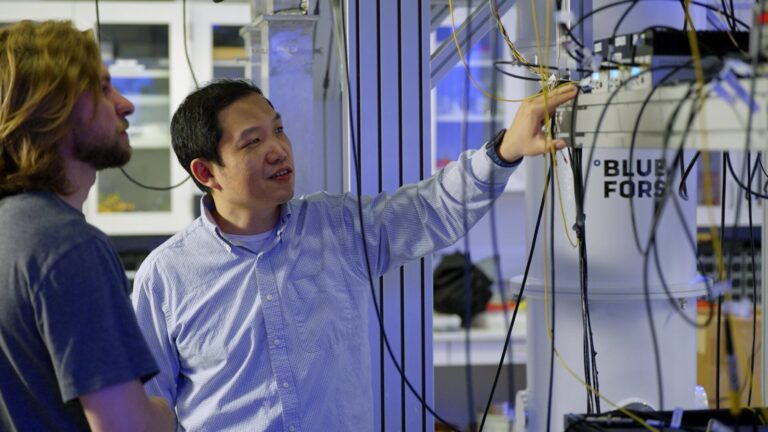

The layout integrates the cryostat, gas handling system, and pulse tube compressor into a single unit, and adds generous rack space for measurement electronics to create a tidy, easy-to-access, compact system – without compromising performance.

Product Highlights

1.0

Ultra-Compact LD

Dilution Refrigerator Measurement System

Services

Total System Care

Total System Care enables you to focus on your work—carrying out research, operating quantum computers, and driving innovation—now, and over the full lifetime of your system.

Tailored to your specific needs, you’ll benefit from a package with an agreed service level and accompanying set of field services that ensure your systems operate at the best possible performance level.

Technical Specifications

2.0

Ultra-Compact LD

Dilution Refrigerator Measurement System

Gas Handling System & Control Software Generation 2

Pulse Tube Cryocooler Configurations

3.0

Ultra-Compact LD

Dilution Refrigerator Measurement System

Options

4.0

Ultra-Compact LD

Dilution Refrigerator Measurement System

Performance Graphs

5.0

Ultra-Compact LD

Dilution Refrigerator Measurement System

Services

Customer Care

We support our customers throughout the lifetime of their system, providing dedicated care to find solutions for any issues. Our technicians and engineers are ready to help you wherever you are located, with prompt service delivered either remotely or on-site.

Related Products

Layout and Facility Requirements

6.0

Ultra-Compact LD

Dilution Refrigerator Measurement System

LD Systems Empowering Research

See Also