Silicon Quantum Computing – Precision at the Atomic Scale

Scaling quantum computing to achieve quantum advantage requires not just bold ideas, but also the ability to execute with extreme precision and purity. Silicon Quantum Computing (SQC) is doing just that, using a materials science approach to engineer atomically precise quantum chips entirely in-house. Their goal? To build the first commercial quantum computer on a platform capable of hosting millions of qubits in a single system.

In this case story, we look at their unique 14|15 Platform, how their incredibly precise engineering capabilities push the boundaries of atomic electronics, and the role cryogenics plays in scaling the platform.

The 14|15 Platform — Harnessing Nature’s Qubits

SQC was founded in 2017, as a spinout from the University of New South Wales, by Professor Michelle Simmons. Michelle is renowned for her foundational contributions to the field of atomic electronics and quantum device fabrication: Simmons’ group, prior to the incorporation of SQC in 2012, created the first single atom transistor. Building on this work, the team at SQC created the 3D atom transistor in 2019, and designed an integrated circuit made with atomic precision in 2022.

Today, SQC’s team consists of over 75 engineers and 20 commercial staff based in Sydney, Australia. Their focus is on scaling qubits, leveraging their application specific systems to deepen customer relationships and delivering the world’s first commercial scale quantum computer in 2033.

The 14|15 platform forms the heart of SQC’s approach. The name references the periodic table (silicon is element 14; phosphorus 15), and is also a description of a powerfully simple, atomic-level architecture.

In their approach to building quantum computers, SQC utilizes silicon in a similar way to today’s microchips, but instead of working with classical electronic components, they use it as a base for individual phosphorus atoms to work as qubits. Quantum information is stored in the spin state of nuclei confined in pure silicon crystal. It’s a marriage of atomic qubits and humanity’s deep understanding of silicon as a computing platform.

The construction of the platform starts with isotopically pure silicon-28, a form of silicon with no nuclear spin in its lattice, creating an ultra-quiet environment for the qubit. Into this pure silicon-28, SQC places individual phosphorus atoms with atomic precision using uniquely designed Scanning Tunnelling Microscopes (STM).

The phosphorus atoms have a nuclear spin which serve as qubits. By placing multiple phosphorus donors within a few nanometers SQC created nuclear spin register capable of sharing a single electron. The electron acts as an ancilla qubit for readout. The shared electron facilitates entangling operations and all-to-all connectivity within the register. This approach has led to the highest Bell-State fidelities and allows processors to perform hardware efficient multi-qubit gates.

Because the qubits are atoms placed in a single, clean host material, there are no nearby dielectrics or different material interfaces to add charge noise: it’s a solid-state vacuum. This material simplicity, plus the magnetic quiet of silicon-28, gives their qubits long coherence times and low error rates. The platform also is inherently robust to bit-flip errors significantly easing large-scale integration constraints.

Another crucial benefit of the approach is size. Since these qubits consist of only two types of atoms, SQC can fit thousands of qubits on a QPU and millions on one chip. “The ultimate aim is to develop a commercial scale quantum computer that will fit in one dilution refrigerator: a scalable, cost-effective solid-state platform that combines the stability of atomic qubits with the scalability of modern chip fabrication. It is the most viable path to make large-scale quantum computing both technically and economically viable,” Michelle says.

Manufacturing with Atomic Precision

Building these atomically precise quantum chips required SQC to optimize their manufacturing processes. The result is their proprietary PAQMan process: Precision Atom Qubits Manufacturing.

The PAQMan process uses scanning tunneling microscopy (STM) techniques to pattern pristine silicon with 0.13 nanometer accuracy, after which phosphine dosing is used to precisely place phosphorus atoms into silicon lattices. Finally, SQC uses molecular beam epitaxy (MBE) to grow layers of silicon that protect the phosphorus qubits from noise.

This approach has resulted in remarkable performance metrics for their qubits: “Our materials science driven approach—combined with being the world’s most precise engineering company—has yielded exceptional results including 99.9% initialization and readout, 99.99% single qubit gate, 99.9% two-qubit gate, 99.5% Bell-state fidelities, and a 98.9% execution of Grover’s search algorithm on our system,” Head of Quantum Engineering Ludwik Kranz from SQC says.

The ability to achieve these numbers is paired with another powerful advantage: speed. “One amazing advantage that in-house chip manufacturing provides us with is a 1-week chip iteration time. We don’t rely on 3rd party foundries for our QPUs, so we have a super-fast iteration and learning time which feeds directly into fast progress and the highest quality systems.”

Having in-house atomic-scale processor manufacturing provides opportunities to rapidly improve chips, but SQC’s competencies go beyond that. The company also designs everything from hardware integration to the classical control systems and software. The ability to control and deliver everything in the quantum computing stack means they can provide valuable solutions to customers even before developing a universally applicable quantum computer.

“We’re a true full-stack quantum computing company. We manufacture the chips with 0.13 nanometer (atom level) accuracy, all the way through to writing software and applications. Because we have that chip manufacturing ability and know-how in-house, we build both gate-based quantum computers and application specific devices which deliver advantage to customers today. Those include our Quantum Machine Learning (QML) AI-Acceleration ‘Watermelon’ and our 20k site molecular simulation and surface chemistry chips ‘Quantum Twins’,” Michelle explains.

Scaling with Help from Cryogenics

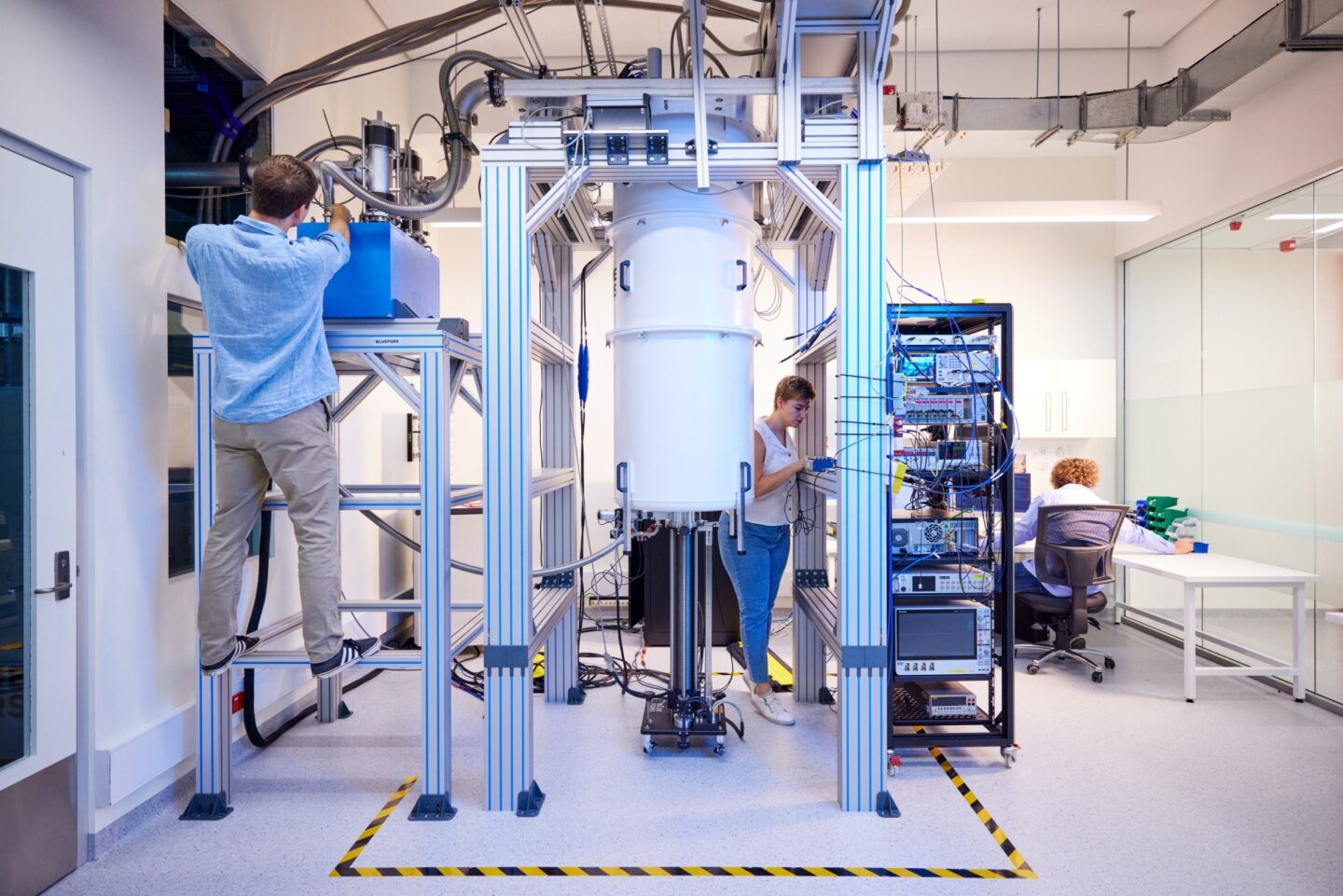

Silicon Quantum Computing’s atomic-level engineering demands equally high-performance cryogenics. That’s where Bluefors comes in. “Our commercial scale quantum computer fits into one dilution fridge. This is exceptional science – leading to superior economics of the commercial system – that requires the very best technology in cryogenic technology. This is why we partner with Bluefors,” Ludwik says.

For their research and development, SQC uses a Bluefors XLD400 System. Thanks to its Fast Sample Exchange System, the XLD has become a foundational element in SQC’s fast-prototyping process.

“With our uniquely quick 1-week chip iteration cycle, characterizing our quantum processors rapidly and without compromises is top priority. The XLD’s bottom-loading Fast Sample Exchange System allows us to test new processors at millikelvin temperatures within a day, without the need to open and close the fridge each time,” Head of Quantum Systems Sam Gorman from SQC says.

The XLD and its Fast Sample Exchange System align perfectly with SQC’s rapid iteration requirements, ensuring that experimental throughput is never slowed by system downtime.

“Overall, the XLD’s reliability, flexibility, and performance gives us full confidence that the cryogenic environment will consistently meet the demanding requirements of our experiments. This is critical for maintaining high-fidelity operations as we scale the number of qubits. The system’s design also makes it straightforward to adapt to evolving experimental needs, whether we’re increasing device complexity or integrating new control hardware,”.

As SQC continues to scale their atomic-scale quantum technology, reliable cryogenic infrastructure plays a vital role in enabling stable qubit performance. Even larger cryogenic platforms will help them achieve their leap to millions of qubits.

“The XLD400 system at SQC is only the start of our scalability journey. As we continue to scale to larger qubit numbers with more control requirements we’ll need the larger cooling capacity Bluefors’ XLD1000 and KIDE platforms. SQCs dense 14|15 technology enables millions of qubits to fit inside a single dilution refrigerator. We see Bluefors’ technology and experience as a key component of delivering such a large quantum computer,” Sam continues.

In quantum technology development, every detail—from cryostat design to system integration—can influence the performance and scalability of quantum devices, so a close collaborative partnership is vital to fuel progress.

“We have particularly enjoyed the professionalism, future-orientated and welcoming approach of Bluefors. The quantum field is an international business and we’re happy and proud to be working with global leaders and suppliers like Bluefors.”

The Road to 2033 and Beyond

SQC’s roadmap is clear: to deliver the world’s first commercial-scale quantum computer in 2033. “Our high-level roadmap sees us rapidly increasing qubit counts now that we have proven our utility scale architecture with a multi-register system with scaling advantages,” Michelle says.

Along the way, SQC are partnering with customers to provide value through quantum machine learning (Watermelon), quantum chemistry and molecular simulation (Quantum Twins) and quantum computing systems (the Chilli Series).

“We’re building a system that is generalizable across quantum computing use cases and are already working with customers to deliver outcomes in AI acceleration, anti-money laundering in financial services, network health and load balancing in telecommunications, grid optimization in energy, and logistics optimization in mobility. In the future, our systems will deepen their deployment with customers to enhance cybersecurity and discover new materials, pharmaceuticals and catalysts.”

SQC’s journey — from the first single atom transistor in 2012 to the first atomic scale integrated circuit in 2022 — is a testament to their belief in atomic precision as the key to scalability. With the right partners in cryogenics and system integration, they are positioning themselves to not just join the next era of computing, but to define it.

“It’s always an exciting time in quantum computing and today is no different. A number of companies are beginning to show commercial usefulness from their systems and devices. We’re a leader in that regard. Commercialization is incredibly important for the industry as a whole, but we can’t make that work unless we have amazing suppliers to make it all happen alongside us. That’s why we’re proud to be a Bluefors partner.”